Pool Refinishing

Tired of painting? Is your pool in need of a makeover?

Palmer Pool Sales now offers EcoFinish High Performance Swimming Pool Finishes!

Palmer Pool Sales now offers EcoFinish High Performance Swimming Pool Finishes!

It took over twenty years, but a new product has now emerged virtually eliminating all of traditional plaster and paint coating shortcomings pool builders have come to experience. It is resistant to chipping, peeling and chalking. It cures in seconds – not weeks, and it is extremely durable, outlasting conventional finishes!

For decades swimming pools were coated in a silky white rubber-based paint finish. In addition to the smooth texture and bright white look, this type of paint was known for its durability against stains and imperfections. During the late 1980’s, government regulations banned some of the most crucial ingredients, that made this product maintenance free. New paints were no longer free of imperfections. Blistering, chipping, peeling, and fading began to appear in a little as six months. This forced swimming pool builders in many regions to switch to plaster finishes. Plaster has its own set of issues, in the from of a long and complicated start-up process (Hot-Start), as well as staining, shrinking, and cracking problems.

Now, EcoFinish has created aquaBRIGHT®, which was scientifically developed to present a solution to these aquatic finish problems. The long-lasting thermo-polymer finish, aquaBRIGHT® is the wave of the future.

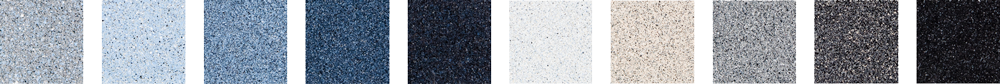

Colors Available:

Features & Benefits:

- Color Uniformity

- Compared to colored masonry finishes, aquaBRIGHT® has a more uniform color across the entire swimming pool and as the pool ages the aquaBRIGHT finish will not “mottle” or fade in larger blotchy clouds.

- Why Pay For Trucked Water?

- If left alone, most curing masonry finishes will dry out and crack if water is not immediately placed in the pool. Because of this, it is a common practice to truck in water to protect the new finish. Once installed, the aquaBRIGHT finish is cured. You can fill that day, the next day or the following week; thus eliminating the need to pay for water.

- What’s A Hot Start?

- Are you looking at a colored finish? Colored Masonry finishes typically require a two week start up process called a “Low alkalinity burn” or a “Hot Start”. This is where you or your pool company will pour muriatic acid into your pool to burn the leaching calcium off the curing masonry finish. Being a hard durable plastic surface, aquaBRIGHT does not require any caustic or complicated start up process. We call our start up process, “Balance and Swim”.

- Pick A Color, Any Color.

- Pigments are like commodities, there can be great variations in cost, depending on the color you choose. Sometimes the difference can be so great it becomes the sole determining factor in choosing the color scheme for your pool. All standard aquaBRIGHT finishes are one awesome low price, so choose away and pick what you like and not what you can afford.

- Test, Add Chemicals And Re-test.

- When did owning a pool mean that you need a degree in chemistry? Old timers used to treat their pools with two things chlorine and muriatic acid. Unlike masonry finishes, the non-porous, smooth and PH neutral aquaBRIGHT finish won’t counter balance with your swimming pool’s water chemistry. We’re not saying with aquaBRIGHT you’ll only need chlorine and acid, but due to the nature of plastic, you’ll spend much less time balancing your water chemistry and more time enjoying your pool with your family.

- Pre-mix To Protect

- Many chemicals need to be pre-mixed with water before adding the product to the pool. Usually this is to protect the finish of the pool to prevent problems like bleaching and etching. Our plastics are chemical resistant and unlike masonry finishes, aquaBRIGHT can be acid washed with very little impact to the surface and the color.